Hydrogen

#WeKnowHow

In order to make use of all the advantages of hydrogen as a climate-friendly energy carrier, valves are required that address all the criticalities of this demanding medium. Siekmann Econosto has the necessary technological expertise and produces valves that withstand quality tests under the most extreme conditions.

Factsheet Hydrogen

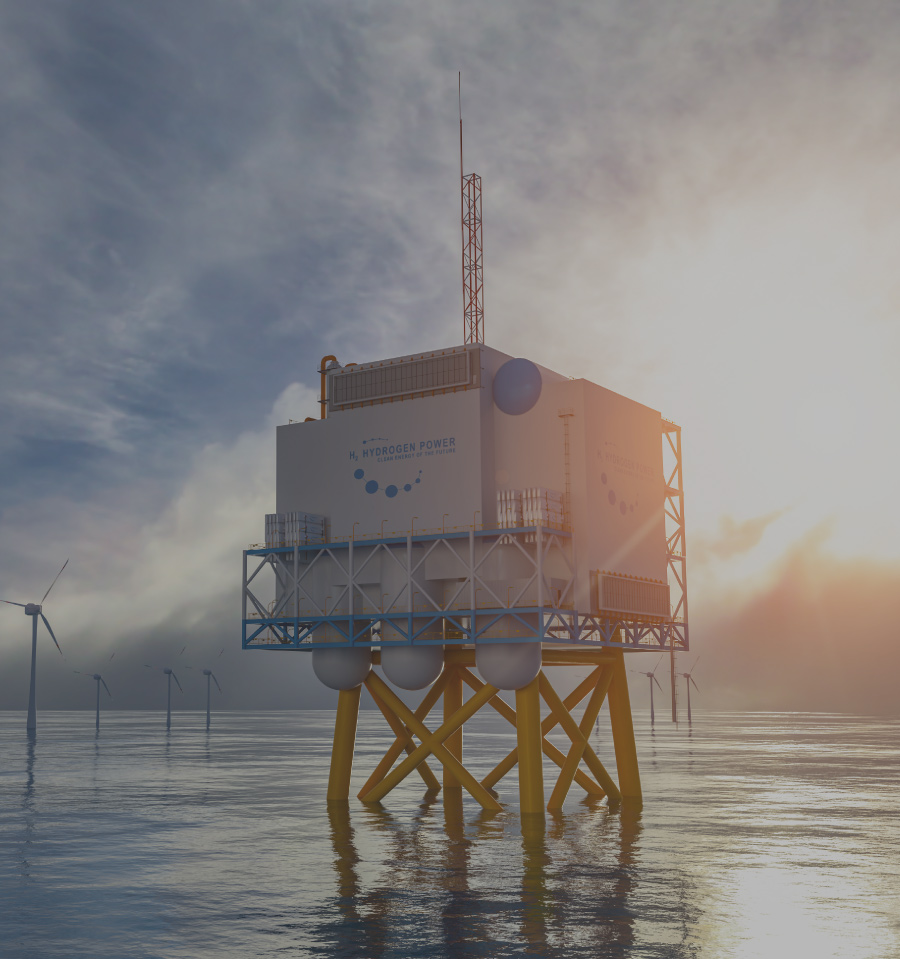

Hydrogen can be produced in various ways, but an increasing number of companies are turning to “green hydrogen” from renewable sources, which can be used by means of power-to-gas technologies as a raw material in the chemical industry, as an emission-free energy carrier for electricity and heat, and as a motor fuel.

The application possibilities are just as varied as the valves that are required for hydrogen production, storage, transport and use. In order to ensure a safe hydrogen infrastructure, the valves used have to meet demanding requirements regarding design, material durability and quality.

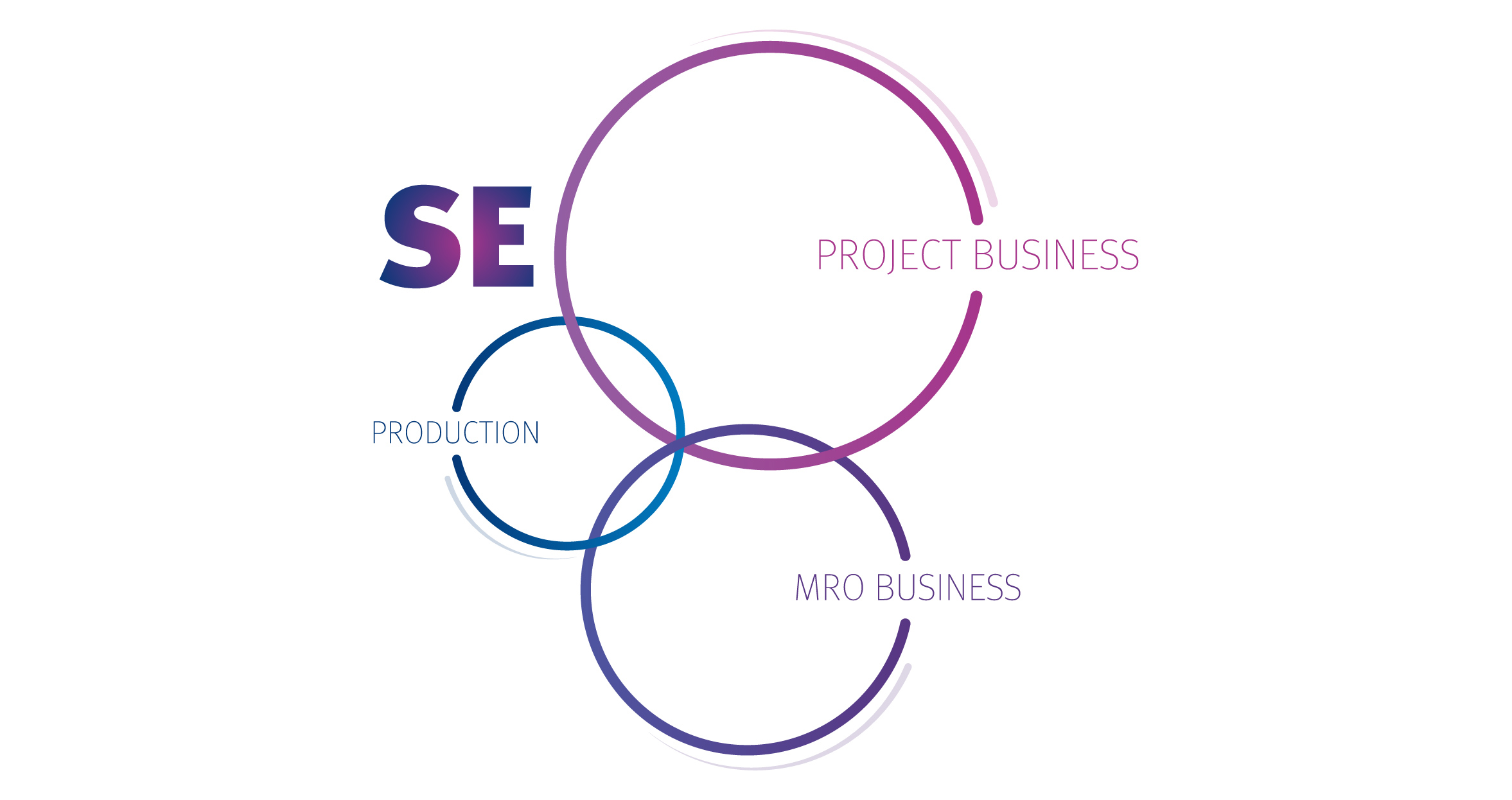

As an expert in the international project business, Siekmann Econosto has a wealth of experience in the field of innovative valve technology and provides system solutions for every phase of the hydrogen production chain.

Valves for

even the most extreme conditions

Hydrogen can be produced by steam reforming or water electrolysis, among other methods. For climate-friendly “green” hydrogen, the electricity required for water electrolysis stems from renewable sources such as wind or solar energy. Cryogenic processes play an important role in the processing of hydrogen, because the gas has a low molecular mass and only liquefies at temperatures of -253 degrees Celsius and below. Liquefaction of the hydrogen makes efficient handling possible, because thanks to the higher density, hydrogen can be stored more effectively in a liquid state and transported more easily to its destination. Valves that are used in the hydrogen infrastructure must be able to withstand extreme pressures and temperature ranges, so they have to be particularly robust. As an expert in industrial valves, Siekmann Econosto places high demands on the selection of materials for the individual valve components. The company makes use of external testing of the materials in a specialised laboratory in order to ensure that the valves guarantee maximum safety.

The materials are tested for the required ductility by means of the Charpy Impact Test at an impact test temperature of -269 degrees Celsius using special testing equipment. The ductility of the material is the prerequisite for the safety of the entire process.

Solutions for

climate-friendly energy systems

Siekmann Econosto collaborates with sub-contractors and partners from all over the world in order to provide innovative system solutions that are both cost-effective and sustainable. Along with its headquarters in Dortmund, the company also has one of the largest valve warehouses in Europe at its site in Zwenkau and is involved as a valve supplier in the construction of some of the world’s largest gas processing projects. With its future-proof valve solutions, Siekmann Econosto is supporting the gradual transition to a more environmentally friendly energy economy and is able to realise customised concepts that contribute to the development of a sustainable hydrogen infrastructure.