Preparation for

oxygen applications

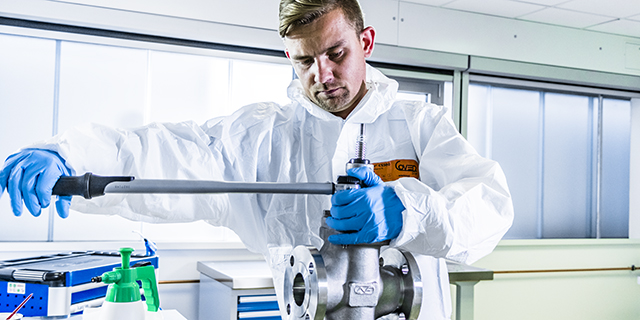

The cleaning of valves for use in the highly sensitive field of oxygen is carried out by our employees in seven specially developed production processes. This involves dismantling standard valves from a wide range of manufacturers down to their individual parts and cleaning them in a complex process in order to ensure the highest degree of purity in accordance with customer and regulatory requirements. Our facility in Zwenkau has specialist equipment, a clean area and clean rooms to ensure that the valves are optimally prepared for use in, for example, air separation plants.

1. Dismantling of commodity valves

2. De-burring & pre-cleaning

3. Ultrasonic cleaning & flushing

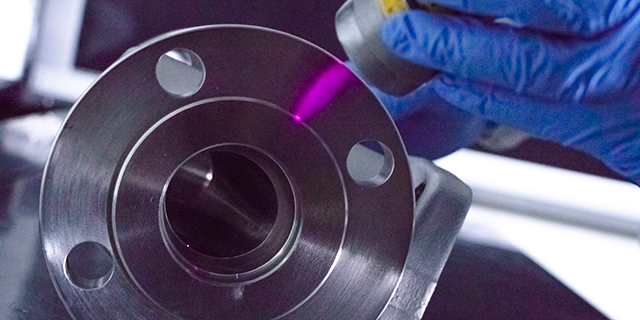

4. Ultraviolet & white light inspection

5. Re-assembly / BAM materials

6. Pressure & function test of cleaned valves

7. Packing in PE-foil with desiccant

If you have any questions or require further information, please contact us at:

info@siekmann-econosto.de or use the contact form.

We will get back to you in a short time.