STORIES OF MISSION ZERO – BREVIK NORCEM

A world first in Norway –

CCS technology for cement production

“Brevik Norcem” had already attracted global attention years before its realisation: the plant, which will have been completed in Brevik, Norway, by July 2024, is the world’s first project designed to capture and store carbon dioxide within an existing cement production plant and is expected to reduce CO2 emissions there by 50 %.

© by Brevik CCS: 20220523-co2fangst-0857

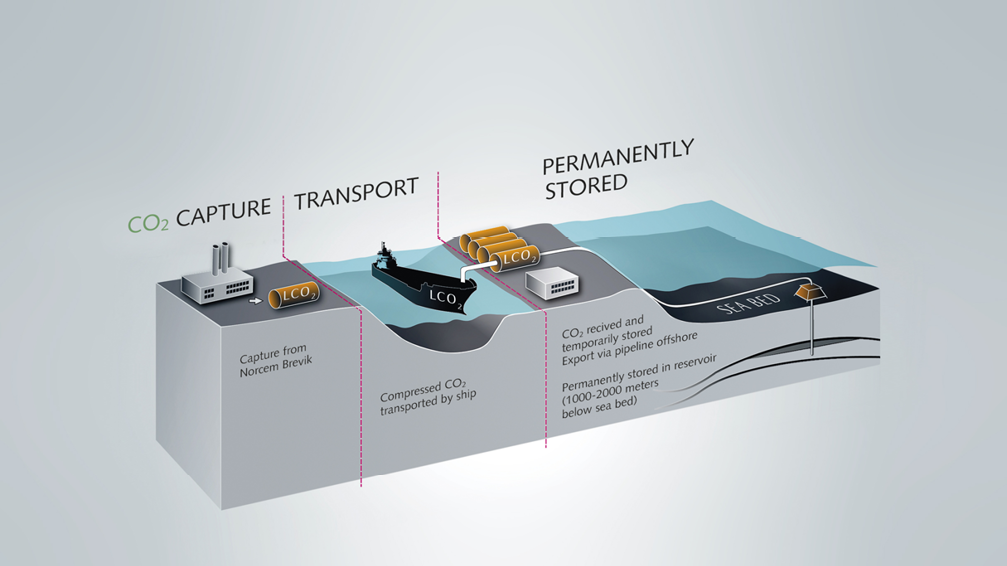

Being open to new technologies and solutions for reducing emissions in environmentally harmful industries. This credo is being practised worldwide in the form of various different concepts. Norway is a pioneer in the field of CCS (carbon capture and storage) technology. In 2020, the government gave the go-ahead for the “Brevik Norcem” project, which had been planned for years, and thus paved the way for the construction of the world’s first CCS technology plant in the cement industry. This poses a major challenge for engineers and technicians, because the CCS plant is being built on the site of a cement plant, with production continuing there around the clock. In future, it is planned to capture and store 400,000 tonnes of CO2 every year. A major innovative project with the aim of transporting the first delivery of liquid CO2 to the Northern Lights

project for permanent storage in July 2024. The Northern Lights project will store emissions deep below the Norwegian seabed.

A key role for the future

This unique project was initiated by a renowned Norwegian corporation and a well-known company that is a subsidiary of the world’s leading building materials group specialising in aggregates, cement and ready-mixed concrete.

The global building materials group employs around 54,000 people at over 3,000 locations worldwide and is involved in a number of different CO2 reduction initiatives with the aim of supplying climate-neutral concrete by 2050. This major project in Brevik plays a key role for the company, and its success could have a significant impact on the future role of CCS in the cement industry.

Safe, reliable SE industrial valves

Siekmann Econosto is supplying Brevik with DIN-standard ball valves and butterfly valves for the construction project. The first delivery of valves arrived in Norway in 2022. As a company that is active throughout the world, Siekmann Econosto is known for its highly effective valve solutions and is committed to supporting climate-friendly industrial concepts. True to the company’s motto: “Let`s make new energy sustainable and affordable”.

CCS technology in Germany?

The world of politics and business is watching Norway with great interest. A successful implementation of the CCS technology plant within a cement production facility and subsequent storage under the seabed could also open the door to CCS technology for Germany. Here, projects involving carbon capture and storage are a controversial issue. Laws and regulations restrict the viability of CCS technology. One of the main risk factors is safety at the final CO2 storage site. The individual federal states are therefore able to prohibit storage within their territories. However, the difficult economic situation and ongoing climate change have led to increased interest in CCS technologies. Additional safety measures and options for carbon capture and utilisation, i.e. the capture and subsequent recycling of CO2, are increasing interest in the possibilities of sustainable use.

© by Brevik CCS: 20220523-co2fangst-0719

© by Brevik CCS: northernlights_illustration_norcem_eng

About Siekmann Econosto

Siekmann Econosto is an internationally renowned supplier of high-quality industrial valves that has stood for outstanding technical performance, safety, quality, reliability and internationality for more than 65 years now. The company provides valves for international plant manufacturers and operators of industrial installations throughout the world and pursues a clear goal: we want to improve our customers’ processes and make them more efficient and more sustainable. Our mission: Let’s make industry work better.

We are perfectly positioned to support our customers with technological expertise, a comprehensive portfolio and many years of experience, and to benefit from the major growth drivers such as the increasing demand for energy and sustainability. The company is part of the Dutch ERIKS/SHV Group, a decentralised family business with a turnover in the double-digit billion range and 56,800 employees in 73 countries.

Stories of

mission zero

Are you interested?

Learn more about a career with us!