STORIES OF MISSION ZERO – SCHWECHAT

Co-processing plant in Austria –

Sustainable mobility through biofuels

A world-famous Austrian oil, gas and petrochemicals company is taking the next step towards sustainable mobility and investing in co-processing technology at its Schwechat refinery site. This major project is characterised by the transformation to recycling-oriented thinking and innovative bio-oil processing.

© OMV Aktiengesellschaft, Title: Chemical recycling plant

The refinery in Schwechat, near the Austrian capital Vienna, is one of Europe’s largest inland refinery and petrochemical sites. Here at the very heart of Europe, the globally renowned company is investing almost 200 million euros in the production of biofuels. The objective is to convert 160,000 tonnes of liquid biomass into carbon-neutral fuels annually by means of co-processing and to reduce its own CO2 emissions by replacing fossil fuels.

How co-processing works

Co-processing involves adding biogenic raw materials during the production of fuel and processing them together with petroleum-based raw materials in a hydrogenation plant. At the refinery in Schwechat, biofuel can be produced from raw materials such as rapeseed oil and sunflower oil, some of which come from local Austrian farms. The well-respected petrochemical company is working continuously to increase the proportion of sustainable raw materials used in its own production processes and is aiming to save up to 360,000 tonnes of fossil CO2 every year through the use of hydrogenated vegetable oil. One major advantage of the co-processing technology is that it is not limited to the use of vegetable oil. It is possible to use waste cooking oil for biofuel production in Schwechat, and environmentally friendly algae oil will also be an option in the future. The co-processing plant provides many innovative options for the production of biofuel. The biofuel the facility produces fulfils the highest quality requirements and complies with strict environmental, social and safety criteria across the entire supply and production chain. The biofuel can be used in all types of vehicles and is an important step towards the realisation of solutions for a sustainable mobility sector.

© OMV Aktiengesellschaft, Title: Chemical recycling plant

Put your trust in SE quality valves

Siekmann Econosto is participating in this major international project and has been supplying Schwechat with ball valves, gate valves, strainers and accessories in accordance with DIN and ASME standards in in the renowned first-class, tested SE quality since 2021. The well-known Austrian plant operator has assigned responsibility for the construction of the co-processing plant to a leading international plant engineering company specialising in process technology. This company is in charge of all the phases of the project, including engineering, procurement services and site management.

Alternative fuels

Biofuels made from processed vegetable oil and other alternative fuels – as part of its in-house sustainability strategy, the internationally renowned petrochemical company is focussing on maximum flexibility regarding the use of sustainable raw materials that utilise existing resources or are based on recycling options. In this way, state-of-the-art technology is combined with decades of expertise in fuel production with the aim of making it available to everyone in the long term. A goal that reflects the SE corporate philosophy:

“Let’s make the new energy sustainable and affordable”.

© OMV Aktiengesellschaft, Title: OMV Borealis Refinery in Schwechat

© OMV Aktiengesellschaft, Titel: OMV Boreals Raffinerie Schwechat

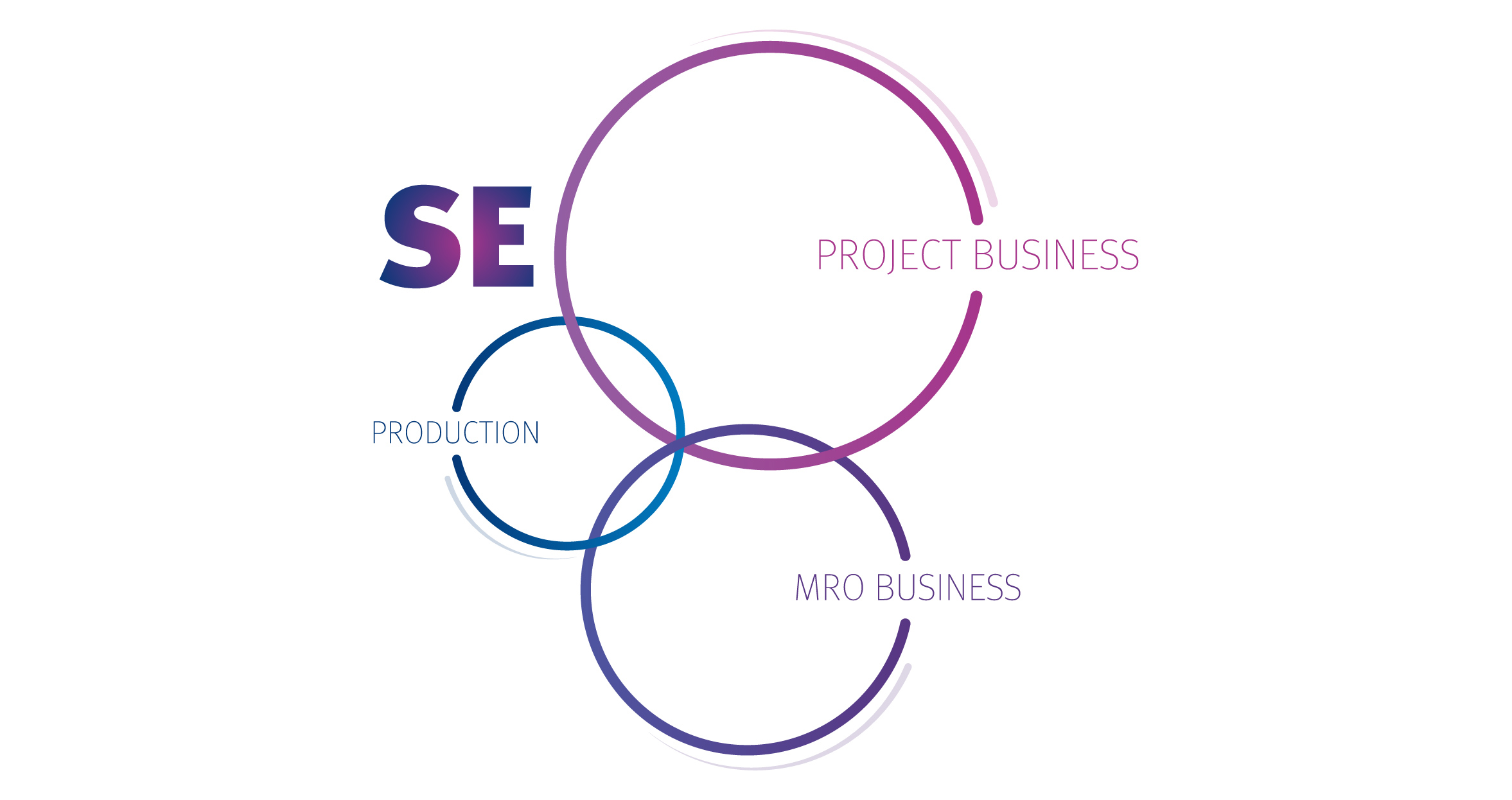

About Siekmann Econosto

Siekmann Econosto is an internationally renowned supplier of high-quality industrial valves that has stood for outstanding technical performance, safety, quality, reliability and internationality for more than 65 years now. The company provides valves for international plant manufacturers and operators of industrial installations throughout the world and pursues a clear goal: we want to improve our customers’ processes and make them more efficient and more sustainable. Our mission: Let’s make industry work better.

We are perfectly positioned to support our customers with technological expertise, a comprehensive portfolio and many years of experience, and to benefit from the major growth drivers such as the increasing demand for energy and sustainability. The company is part of the Dutch ERIKS/SHV Group, a decentralised family business with a turnover in the double-digit billion range and 56,800 employees in 73 countries.

Stories of

mission zero

Are you interested?

Learn more about a career with us!